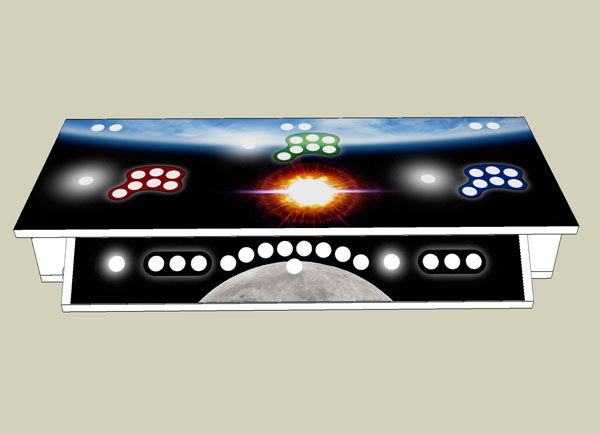

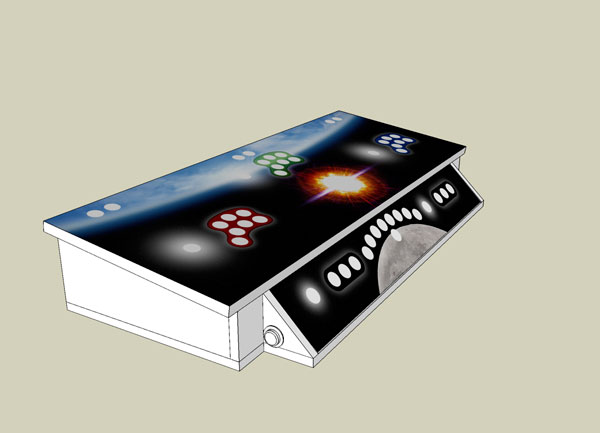

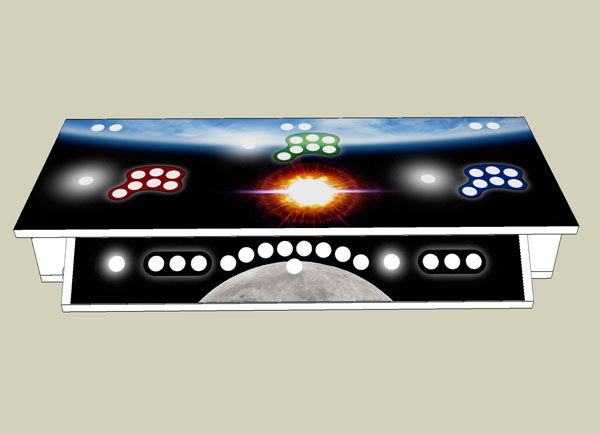

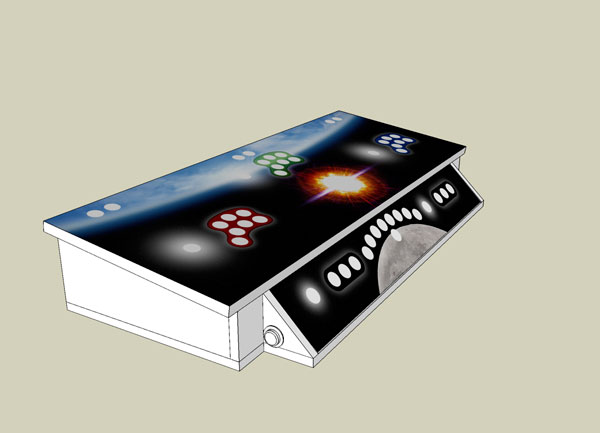

Wow, long time. Anyway, have finally got around to doing some more work on this project. First, I have finalized my control panel design and artwork, which you can see below.

It is pretty similar to what I had planned, except that I will now be incorporating artwork (placed under lexan) on my lower panel. The reason for the slant is to provide a better angle for driving games using the 7″ mini racer wheels along with the dual TurboTwist2 spinners. Also have incorporated lighted buttons on the sides of this lower panel for limited use in pinball and such. The buttons in the center surrounding the image of the moon will serve various admin functions in MAME.

The top of the panel still has the 3 players (2 Happ 8 ways and 1 UltraStik), along with the U-Trak trackball with RGB lighting.

Mostly what was finalized was the artwork and placement of the buttons and sticks. I finally broke down and purchased some super high resolution artwork, so the design should hopefully look really good. The overall theme has sort of merged into the sun (the lighted trackball) going supernova and the player is seeing this from a little behind earth and the moon.

Also finished up the marquee, which now has a solar eclipse with a few more rays coming off it. Again, high resolution images, so I am hoping for the best.

So after designing this thing I thought it might be a good idea to do another mock-up. This time it was actually to scale (or as best as I could make it) and included the artwork I created so I could test button spacing. I didn’t make it functional, but it made me confident enough in my design to go ahead and get my artwork printed and to continue with the construction.

So what’s next? The week after next I will be heading to my hometown where I will be using a pretty good wood shop and the help of one my moms friends to help get this thing cut. After that I will be using the 3 full days or so before Thanksgiving to try to get the pieces assembled and painted. Assuming everything goes to plan, after that it will be back to Seattle where I will start on wiring and getting it set-up…